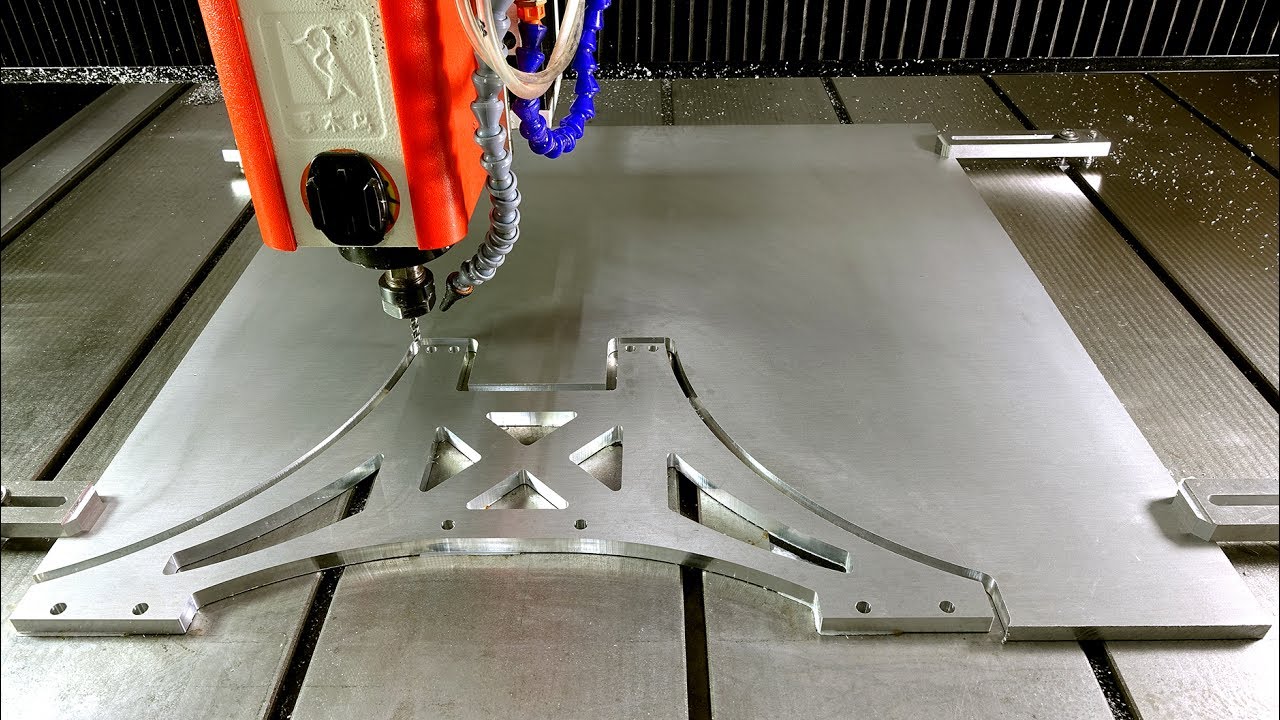

Metal CNC cutting mica offers an unparalleled level of excellence and precision to enhance various projects across diverse industries. With its advanced technology and exceptional capabilities, metal CNC cutting mica brings forth a new era of innovation and efficiency. This cutting-edge process combines the strength and durability of metal with the versatility and precision of CNC machining, resulting in remarkable outcomes that surpass traditional methods. One of the key advantages of metal CNC cutting mica is its ability to deliver unparalleled precision. The use of computer numerical control CNC technology ensures that every cut and detail is executed with utmost accuracy and consistency. This level of precision allows for intricate and complex designs to be achieved effortlessly, enabling a wide range of possibilities for projects in fields such as aerospace, automotive, electronics, and more.

Furthermore, metal CNC cutting mica showcases exceptional durability and strength. By utilizing high-quality metals, such as aluminum, steel, or titanium, the resulting components or parts exhibit superior robustness, making them suitable for applications that require longevity and resilience. Whether it is constructing lightweight yet sturdy aircraft components or manufacturing heavy-duty machinery parts, metal CNC cutting mica provides a reliable solution that withstands demanding operational conditions. The versatility of metal CNC cutting mica is yet another reason for its widespread adoption. This advanced process can be applied to a multitude of materials, including stainless steel, copper, brass, and various alloys. As a result, it caters to a diverse range of projects, accommodating different industry requirements. Whether it is fabricating intricate electronic components or creating decorative metal artwork, metal CNC cutting mica proves to be an ideal choice that offers endless possibilities.

Moreover, metal CNC cutting mica significantly enhances productivity and efficiency in manufacturing processes dich vu cat laser theo yeu cau. The automated nature of CNC machines ensures swift and consistent production, reducing human error and minimizing downtime. This streamlined approach not only saves valuable time but also optimizes resource allocation, resulting in cost-effective solutions for businesses. Additionally, the ability to replicate designs accurately allows for efficient mass production, catering to large-scale projects with ease. In conclusion, metal CNC cutting mica represents the epitome of excellence in precision manufacturing. Its unrivaled precision, durability, versatility, and efficiency make it an indispensable tool for a wide array of industries. Whether it is for aerospace, automotive, electronics, or other sectors, metal CNC cutting mica provides the means to elevate projects to new heights, enabling innovation and pushing boundaries. By embracing this cutting-edge technology, businesses can unlock a world of possibilities, achieving exceptional results that surpass traditional methods.